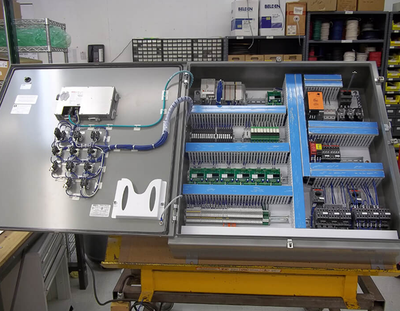

Industrial Control Panel

Industrial Control Panel and so much more. System integration and people you can count on.

Xtreme Automation LLC knows- Engineering is Important especially when it comes to Industrial Control Panels Industrial Control Panels are essential to the effective operation of several industrial operations. These panels serve as the brains of the industrial automation system, enabling operators to control and manage sophisticated machinery and equipment. Engineering plays a critical part in the flawless functioning of these control panels. This post will discuss the value of engineering in Industrial Control Panels and how Xtreme Automation engineering helps to improve their performance. When you get a control panel from us you will be glad you did, and your electrician will also be happy. Often local electricians feel overwhelmed when bidding for a job in the industrial industry since ever job is completely different. Also, it's intimidating for them when the schematics are hard to read and unclear what is their scope. When we build control panels custom user-friendly schematics are always provided and this helps in a major way. The bid is more accurate, and the work is often done right and on time. We care about all the details not just the ones you notice.

Design and Individualization Engineering is the foundation for designing and customizing industrial control panels. Control experts use their knowledge to customize control panels for particular industrial applications while taking into account aspects such as the kind of equipment, processes, and environmental conditions. They guarantee that the panel's design precisely complies with the industrial standards by using cutting-edge control engineering methods, maximizing overall efficiency and safety. All of our system includes 2-3 quotes to make sure we have covered all possible options. Designing a system is critical to making sure our customers are happy and that the system performs.

From Manual Controls to High-Level Automation: Tailoring Solutions

In the world of automation, needs vary widely. Some operations require intricate high-level automation, while others can thrive with manual control panels. At Xtreme Automation LLC, we cater to both ends of the spectrum and everything in between. Our push-button panels can be as simple or as complex as your operations demand.

The Power of UL 508a Certification

Safety and compliance are non-negotiable aspects of industrial automation. Our UL 508a certification speaks to our commitment to upholding the highest safety standards. When you work with us, you’re not just getting a control panel; you’re getting peace of mind knowing that your operations are backed by certified solutions.

Schematics: The Unsung Heroes of Precision

While push buttons are the visible interface, the true magic lies in the schematics. Our UL 508a panel shop not only designs panels but also creates schematics that are easy for electricians to read and understand. This attention to detail can significantly impact your project’s timeline and cost, ensuring that electricians can work efficiently without costly errors.

Experience the Xtreme Difference

At Xtreme Automation LLC, we’re not just in the business of creating control panels; we’re in the business of transforming industries. Our push button panels are a testament to our dedication to precision, customization, and excellence. Whether you need manual controls or high-level automation, our team is ready to guide you through the entire process, ensuring that your operations reach new heights of productivity and efficiency.

Don’t settle for less when you can have the best. Contact Xtreme Automation LLC today for a free quote and explore how our push button panels can revolutionize your operations. Your success is our mission, and we’re here to make it a reality.

By using technology and innovations, Xtreme Automation engineers goes above and beyond in this process to create control panels that are superior to industry standards. A more flexible and agile control system that can scale up and down as needed is produced by this method.

Integration of Diverse Components Various parts, including programmable logic controllers (PLCs), human-machine interfaces (HMIs), sensors, switches, and communication modules, are included in industrial control panels. A thorough grasp of control engineering concepts is needed to integrate these components properly. These components are expertly connected by engineers, providing smooth communication and data flow between them. Engineering knowledge from Xtreme Automation promotes a smooth integration process that allows real-time data monitoring, exact control, and quick reaction to changing circumstances. This integrated strategy improves operational effectiveness and helps to cut downtime. You don't know what you don't know. We know automation and have well rounded experience to help tackle and prevent issues.

Security and industrial environments, safety is of utmost importance, and control panels must adhere to strict safety regulations. Control engineers are essential in making sure that these panels follow sector-specific safety standards and guidelines. Engineers evaluate possible dangers and develop safety measures to successfully minimize them via comprehensive testing and analysis. Xtreme Automation engineers uses redundant systems and fail-safe procedures while designing control panels. A secure working environment is further ensured by ongoing monitoring and remote access capabilities, which allow quick answers to any safety issues.

Optimization and Efficiency is a crucial component of industrial processes since it has a direct influence on output and resource use. Control engineering focuses on maximizing the performance of control panels by lowering energy use, cutting waste, and simplifying procedures. To find areas for improvement, engineers hone control algorithms, put predictive maintenance techniques into practice, and use data analytics. Modern automation solutions from Xtreme Automation engineers raise the bar for efficiency. Control panels can adapt to changing circumstances, self-optimize, and constantly improve their efficiency by using artificial intelligence and machine learning.

Troubleshooting and Remote Monitoring the Internet of Things (IoT) and the Internet of Things (IoT) have changed how we see the world. Industrial Control Panels are now constructed with connection, enabling operators to view and manage the panel from a distance. By using these developments, Xtreme Automation engineering is able to provide complete solutions for remote monitoring. Businesses can identify problems early thanks to real-time data visualization, predictive maintenance alerts, and remote diagnostics, which save downtime and boost overall productivity. Our team is always willing to go onsite for service and support. Onsite isn't always the best option so we offer award winning tech support that allows us to login and see exactly what the issues are and fix them. When you call for support, you will talk with an actual PLC programmer not a glorified secretary.

Conclusion

Industrial Control Panel creation and operation are fundamentally influenced by control engineering. Engineers make sure that these control panels enable efficient and streamlined industrial operations via careful design. This significance is taken seriously by Xtreme Automation engineers, which pushes the frontiers of innovation to provide control panels that not only satisfy industry requirements but also go above and beyond, advancing industrial automation into a more effective and productive future.

Call Xtreme Automation LLC for all of your industrial control system needs.

We are a full-service panel shop, design, build, program, train, and support. We are not just system integrators we are people you can count on.

(785) 285-8288